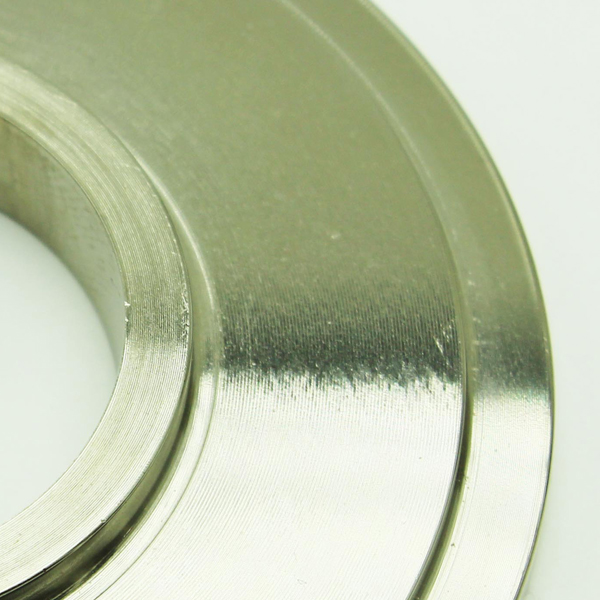

Electroless Nickel Plating

Electroless Nickel Plating uses a solution that is a nickel phosphorus alloy. Electroless Nickel plating provides a bright finish. Composition of the plating solution can be tailored to suit different applications. TPG offers low phosphorus, medium phosphorus and high phosphorus (non-magnetic) electroless nickel plating. Medium phosphorus electroless nickel is used for corrosion and wear resistance. High phosphorus electroless nickel delivers a pore free barrier coating protecting the underlying substrate from attack and offering outstanding corrosion protection and chemical resistance. Electroless Nickel plating delivers an even thickness of deposit.

Applications

The uniformity of coating achieved with Electroless Nickel lends itself to the plating of irregular shaped components, with inside corners and cavities are not too thinly coated and outside corners not too thickly coated. It is extremely resistant to corrosion and therefore suited to plating parts used in harsh environments, such as in the defence, oil & gas, and marine industries. In these applications Electroless Nickel can help extend the life of a part, therefore reducing the costs of replacement and repair.

Our Expertise

TPG have considerable experience in applying electroless nickel to a range of metals including aluminium, kovar, copper and steel etc.

Technical Information

| Types | Plating Methods | Base Materials | Properties | Specifications | Density p(kg/m3) | Melting Point Degrees Cent. | Electrical Resistivity (10-8 Ωm) at 0°C (273.2°K) |

|---|---|---|---|---|---|---|---|

| Medium | Jig/Vat/Rack, Barrel, Selective | Copper Alloys, Steel, Aluminium, Die Castings, Kovar | Hardness, High Corrosion Resistance, Uniform Deposit, Wear Resistance | DEF 03-5 superseded by BS EN ISO 4527, AMS 2404, MIL-C-26074, ASTM B656, ASTM B733 |

8000-8200 | 880-980 | 4-7 |

| High Phosphorus, Non-magnetic | Jig/Vat/Rack, Barrel, Selective | Copper Alloys, Steel, Aluminium, Die Castings, Kovar | Hardness, High Corrosion Resistance, Uniform Deposit, Wear Resistance | DEF 03-5 superseded by BS EN ISO 4527, AMS 2404, MIL-C-26074, ASTM B656, ASTM B733 |

7600-7900 | 880-900 |