Palladium / Nickel Plating (PdNi)

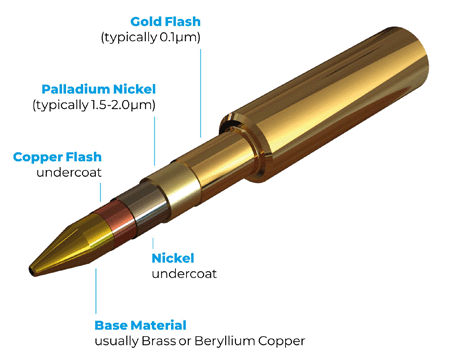

Palladium Nickel alloy is now being used a substitute for gold plating, providing a functional alternative at a much lower cost. Originally developed to resolve cold welding occurring in the mating of connectors plated with cyanide gold deposits, before the introduction of acid gold solutions it has excellent electrical properties for contact resistance and solderability.

Applications

Palladium Nickel is most commonly used to protect and improve contact resistance with electrical connectors but it can also be used as a replacement for gold in electronics for products which require soldering or wire bonding. Also available with gold flash.

Our Expertise

TPG have refined their PdNi process sequence over many years, combining new solution technology with in-house expertise to offer a cost effective, stress free coating for components.

Technical Information

| Types | Plating Methods | Base Materials | Properties | Specifications | Density p(kg/m3) |

|---|---|---|---|---|---|

| Palladium/Nickel | Jig/Vat/Rack, Barrel, Vibro barrel, Selective | Copper Alloys, Steel, Aluminium, Die Castings |

Ductility, Conductivity, High Corrosion Resistance, Good wear resistance, lower cost compared to gold | Customer Specification | 11100 |